GFRC is of particular interest in the Iranian market. Logically, there will be a lot of news on this topic soon. If you are not familiar with Glass Fiber Reinforced Concrete (GFRC), you should. GFRC is a specialized form of concrete. It is a cement-based composite material reinforced with alkali-resistant glass fibers.

Glass fiber reinforced concrete (GFRC) consists of cement or cement hydration products plus sand and glass fibres. Fiberglass is used as reinforcement for concrete. Fiberglass was first used to reinforce cement and concrete in Russia. However, it was eroded by the highly alkaline Portland cement matrix.

What is GFRC?

GFRC is a fiberglass fabric based on interconnected pieces and so-called crushed pieces, which have high tensile and gravity strength, although they are much weaker in terms of compressive strength. But it can have a high resistance with the considered composition. Different materials and sand can be used in this set. Fine sand, cement, polymer (usually an acrylic polymer), water and other additives, and alkali-resistant fiberglass will be used to make it. It is expected to include an important part of the construction projects in the future.

How to Prepare Glass Fiber Reinforced Concrete (GFRC)

Of course, the production methods will be different based on the parameters that are considered for this product. But in general, how to prepare reinforced concrete or GFRC like this.

Glass fibers of 10 to 50 mm in length and a few microns in diameter may be added up to 5% by weight and mixed with cement and water in a bowl or paddle mixer. Small amounts of lubricant additives such as polyethylene oxide or methyl cellulose may also be added to the resulting mixture. The resulting mixture can be sprayed or poured into a mold.

Products can also be produced by extrusion or by injection molding process. In some processes, the edges can be cracked in place and simultaneously sprayed onto the production die with a mortar of suitable consistency. It is very efficient and convenient for roof and sheet molding.

Main Uses of GFRC

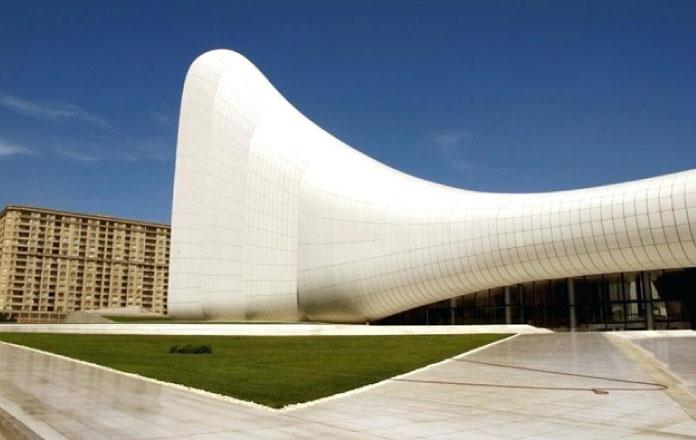

In the Iranian market, GFRC is used for special purposes other than external construction. Likewise, it can be readily used in the construction of domes, columns, decorative ceilings, walls, statues, fences, and decorative parts and textures. One of the most important elements is the use of GFRC in the building facade and display design. In addition, it is one of the best and most popular options available in projects such as docks, floating sea bridges, cable-laying operations channels, water channels and reservoirs.

In addition to these things, it can be said that it is placed in front of concrete as a facade and in terms of speed of implementation, it is a great choice.

- Building renovation works

- Water and sanitation works

- Bridges and tunnels covering panels

- How to make a permanent mold

- architectural cladding

- Sound and screen barriers

It will also be one of the most important primary uses for GFRC concrete.

Benefits of using GFRC

The use of this concrete facade has several advantages, including:

- Materials are used in the optimal way: Less materials are used in GFRC than in other methods of interior and exterior design.

- It is possible to perform on different levels: it can easily be performed on external surfaces, walls and ceilings. Similarly, reinforced structure is also available in the market, which will have perfect quality. Compared to other interfaces, GFRC is installed on many levels better.

- It has high weather and fire resistance: it can show special technical toughness well against high temperatures. In addition, it is no problem to use GFRC in wind, rain, freezing, etc.

- Suitable Weight: The light weight makes this material easy to install and transport. This concrete can be applied on sloping surfaces.

- CAN BE USED INDOORS AND OUTDOORS: It doesn’t matter, you can use GFRC for indoors or outdoors. It is very light, durable and, of course, one of the best options in terms of price.

GFRC in the Iranian market

GFRC is suitable for both indoors and outdoors, so it has a special generality. In addition, it is very light, resistant and durable. For some time now, Dry Interface or GFRC will be used a lot in Iran. Many of the building projects that you see in the city that have been built recently, will eventually be a generic form of this material.

The main advantage that made GFRC popular in Iran is its low cost and possibility of implementation at different levels. This feature means that the scope of use of GFRC is much wider than you can imagine. On the other hand, glass fiber reinforced concrete has a very beautiful appearance and, unlike concrete, does not lose its usual structure after a while.

The best producer of GFRC in Iran

Another important question that arises in the GFRC market is whether it is possible to trust local sellers and purchase GFRC materials? Nowadays, this work has to be done by experience and by relying on modern technical knowledge. Otherwise, the amount of wrong combinations would be one of the most common problems plaguing projects.

On the other hand, buying from a place with high reliability and world-class standards is really difficult these days. However, the price advantage is also very important. If you are looking to buy GFRC at a reasonable price, you should pay attention to this issue, only a few centers in Iran are implementing these materials based on international standards. There are devices to implement GFRC that facilitate the manufacturing process.

Source: Iran Framco