Technical specifications of the resin hardener

In the engine house of central heating systems, a resin hardener is used to produce soft, sediment-free water in order to prevent scale from sedimentation of pipe walls, hot water boilers, and steam boilers.

What is hardened resin?

Tempering Valve Price: The resin hardener includes a package consisting of a metal or fiberglass (FRP) cylindrical tank with a multi-way valve and a water and salt tank for resin regeneration. The tap in resin hardeners can be manual, automatic and semi-automatic. Resin hardeners work by replacing the calcium and magnesium ions in hard water with sodium ions in the resin. These resins must be renewed periodically for better performance and efficiency. This is done by passing water and salt over the resin.

The resin hardening machine usually has a valve at the top for material inlet and a valve at the side for check and service. Water enters the device from the top and passes over the resin materials and is finally transported to the cellulo valve by the installed water collectors.

resin hardening properties

Mineral resin hardness components

Types of resin hardeners in terms of body material

Types of hardness according to the service valve

Solids are divided into two types in terms of service valves

Fully automatic resin hardener is a system that automatically regenerates resin after descaling and water hardness. This procedure is performed by the fully automatic valve and, according to the programming given to the system by the diagnostic kits, the fully automatic valve is given the command for backwashing and resin recovery. In terms of initial cost, fully automatic valves are about 70% more than manual valves, but are more economical in terms of efficiency and the amount of water wasted on the set schedule. The operation of the fully automatic hardener depends on the amount of current or through time adjustment.

Resin hardeners that are backwashed and resin regenerated by the operator using a three-position manual valve (Celulo valve) are called semi-automatic hardeners. The main difference in this type of hardener is only in the backwash valve, which in the semi-automatic sampler does not have the ability to be programmed to replenish the resin and must be performed by the operator continuously. The resin hardening valve position change is semi-automatic for manual backwashing.

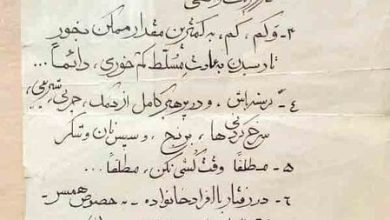

Technical specifications of the resin hardener

Calculation of the hardening ability of the resin

In order to obtain the hardness capacity, we need three general parameters of total water hardness, water flow rate and device operation time. Other factors are also effective in determining the hardness capacity of the resin, such as the type of solid absorbent surface, the type of resin exchange, the amount of contact time to regenerate the type of exchange material, the water quality and the amount of regeneration materials. According to the following formula, the capacity of the resin hardener is determined.

Resin hardness capacity (green) = (resin hardness from passing water * device hardness to input water hardness * 24 * 60) / 17.1

The amount of water passing through the resin hardener is in GPM and the hard water inlet into the hardener is in PPM.

The amount of silica in the hardener

A special resin (zeolite) is poured into the tank at a height of 75 to 200 cm, about half of the height of the main cylinder of the hardening source, and then silica stone is poured before that.

The process of washing and regeneration of the hardening machine resin

To regenerate the resin, during the process, the sodium ions in the brine solution are replaced by calcium and magnesium ions, and the resin inside the hardener tank is regenerated and will be able to solidify again.

Water quality is determined by a series of physical and chemical properties. Some important properties of water include total hardness, total dissolved solids, dissolved solids, and pH, which are directly affected by the source of the water supply. Water is used in several ways, including drinking, washing, washing, and cooking, and in industrial uses, including heating and cooling systems, boilers, and cooling towers. The presence of solids and minerals in water for domestic use may endanger human health and, in industrial use, cause sediment formation in pipelines and equipment. The formation of deposits in the piping system causes clogging and, in addition to clogging the equipment, reduces efficiency and reduces proper heat exchange. Tempering devices can be used to reduce hardness. Hardeners are available in various models, the most commonly used being magnetic hardeners and resin hardeners.

Some ions in water such as calcium and magnesium as well as divalent and polyvalent cations cause precipitation or foaming. To prevent damage to equipment that comes into contact with water, a resin hardener can be used.