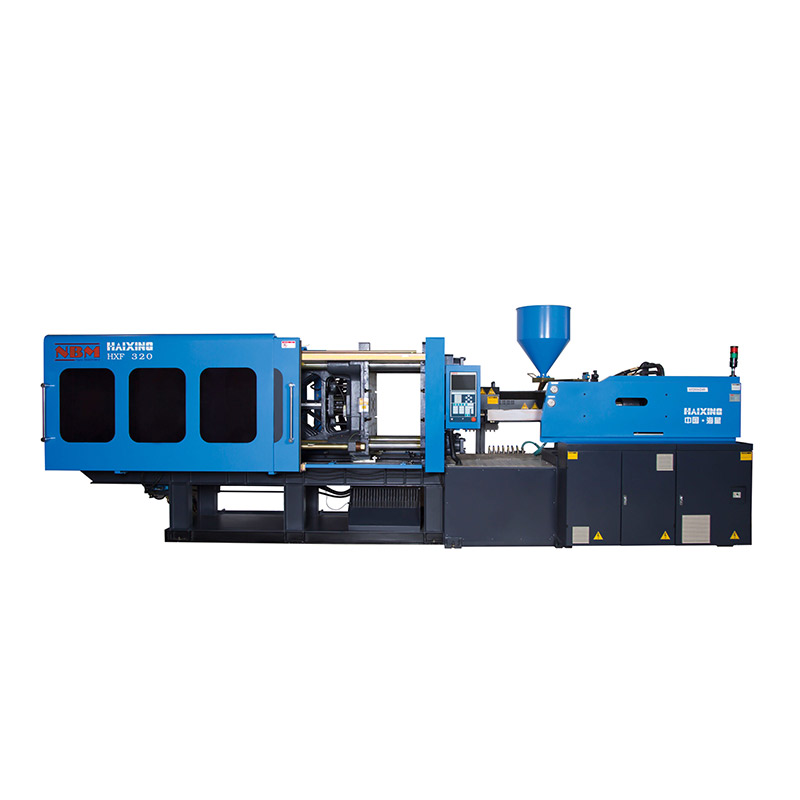

Using an injection machine is one of the most convenient, common and most important methods for shaping polymers. After the emergence and development of plastics, efforts were made to build devices that could easily mold plastic raw materials into the desired shape and led to the invention of the injection machine.

But before the creation of today’s modern injection machines, the work of plastic molding was very difficult, so at the beginning, the molds were prepared with great care and effort, and they were installed in hand clamps, and a cylinder with a piston was installed on them. And the surroundings of the cylinder were heated by the flame, and after the material melted, the material inside the cylinder was injected into the mold with the high pressure of the piston, and after the material inside the mold was cooled, the clamps were opened and the mold was separated and the product was removed from it, and all these steps were done manually, until machines were produced Modern injections today.

The first injection machine operating in a primitive way was manufactured in America in 1872, and the first advanced screw injection machine was recorded. In 1946, in America, by James Watson, the main task of the injection machine is to convert solid plastics (micro-particles or polymer granules) into liquid and liquid plastics and transfer them to the mold so that the liquid materials are always ready to be injected into the mold.

Click to see the price of the plastic injection machine.

Types of plastic injection machines

Plastic injection machines are mainly classified on the basis of the amount of clamp force, the higher the clamp force in the machine, the more it allows to produce larger and heavier parts. The important parameters of the machine are: clamp force, injection unit capacity, distance between guide rails, cycle rod hole, min. mold height max. Plastic injection machines are divided into three general categories: hydraulic, electric, and hybrid, and in the following, we will learn more about these three machines.

1- Hydraulic plastic injection machine

Plastic injection molding machines have always been the only option available to manufacturers until the Japanese company introduced the first electric machine in the early 2000s. Here are some advantages of a fully hydraulic injection molding machine:

Low price The base price of these devices is much lower than other options.

– Cheaper replacement parts: If the parts on the machine are replaced due to a malfunction or the life of the parts has expired, replacement parts can be found more easily and at a lower cost.

– The strong parts of the machine’s hydraulic parts are more wear-resistant, so they are more durable than other types.

– The strength of the hydraulic forming machine has exceptional clamping force. Historically, hydraulic molding machines were the only option available to manufacturers until a Japanese manufacturer introduced the first electric machine in the early 2471 century. It is the first and oldest type of plastic injection machine, which is gradually disappearing from the industry.

2- Electric plastic injection machine

As mentioned earlier, electric plastic injection molding machines were first developed in the 1980s and quickly gained popularity. Here are some advantages of fully electric plastic injection molding machine:

– Energy Efficiency These devices operate when electrical energy is used, i.e. the motor output is only equal to the required load.

Less time in this model, no oil leakage. Also, not using oil means not changing the filter, which reduces consumption costs.

– Faster process: These devices are digitally controlled, meaning the process is repeatable and requires no monitoring.

– Clean operation, since no oil is used for this device, it is safe to use this device if these parts are usually made of medical grade parts. , in a separate, clean part of the room. As mentioned earlier, electric plastic injection molding machines were first developed in the 1980s and quickly gained popularity.

3- Hybrid plastic injection machine (assembled)

According to some, hybrid models give the best plant efficiency by combining the advantages of using an electric and hydraulic drive. Here are some of the advantages of the hybrid injector:

The various possible combinations of these devices create new degrees of design flexibility.

Best case for hybrid molding machines that combine the energy savings and accuracy of an electric model with the power generation capability of a hydraulic unit.

– The motor that AC replaced with DC motors is replaced in fixed speed hybrid models of variable speed pump motors, so the pump only operates when necessary and the necessary oil is used to improve the efficiency of the process.

Fewer Breakdowns These devices require less maintenance and are less damaging than all-hydraulic or electric models.

– Price-wise this model is well positioned among all hydraulic molding machines and all electric molding machines in particular and makes it a cost-effective choice. For medical device manufacturers, according to some, hybrid models by combining the advantages of using an electric and hydraulic drive give the best plant efficiency.

Steps to make a plastic injection molding machine

In the following, 6 stages of the plastic injection process are introduced and reviewed:

1– prejudice

The injection machine consists of three main parts, the mold stage, the clamping stage and the injection stage. in review How does a plastic injection machine work? We understand that fastening includes the part of the machine that holds the mold closed during the injection process and opens it afterwards. The molds are mainly composed of two halves, which must be held together by this part during injection.

2– Injection (Injection)

At the injection stage, the plastics, usually in the form of pellets, enter a funnel at the top of the machine and from there enter a cylinder surrounded by heaters. And after heating, the granules turn into molten state or resin inside, the materials are inverted by means of spiral.

As the screw rotates, the material is also pushed forward, and when enough material is stored in the front of the screw, injection is done by the nozzle, and the molten material is pushed into the die channel. The speed and amount of pressure depends on how much the screw rotates and the diameter of the nozzle. In the way some plastic injection machines work, a basic piston is used instead of a screw.

3– analgesic

when you know How does a plastic injection machine work?We learn that the dwelling phase involves a pause in the injection process so that both the magma inside the cavities is completely filled and the formed gases are removed from the compact chambers.

4– cooling (cooling)

At this point, the melt cools until solid and can be removed from the mold. Otherwise, there is a high probability of changing the shape of the product.

5Open the templateOpen the form)

In this part the riveting section is opened so that the two mold halves are also opened and ready to go.

6 – eviction (Throw)

in How it works When the part is removed, several rods with a plate perform the process of removing the part from the mold. The runners and channels of the unused work piece and the residue are separated from the piece and cleaned to prepare for melting again.

Advantages of plastic injection

- High production speed

- A variety of materials used in this method

- Save the workforce

- Less material waste

- Minimize post-injection operations in product production

- easy to use

Rafiei Machine Plastic Injection Company with years of experience in producing injection machined plastic parts How does a plastic injection machine work? He has knowledge and has always used his mastery of how machines work throughout the plastic injection process. To order and learn from it Tariff and cost of purchasing a plastic injection machine You can also call the company’s support number to receive expert advice from group advisors

retrieved from: injection molding machine