Glass Label Printing (Transparent)

The glass sticker is made of PVC. The fact that the glass label is colorless and transparent makes it visible from both sides. Therefore, it is used for installation on glass, materials with a bright background and in places where the color and visibility of the background space are important. The clear glass decals in this modern art print set are printed in very high quality and in the shortest possible time. Stay with us to learn about this type of print poster.

What is glass label printing?

Basically, stickers are stickers made of 100% waterproof and washable PVC materials. The clear or glass labels are colorless and you can see the color of the work area and the other side of the print. Most often, clear adhesive back label printing is installed on glass and light background materials. Due to the transparency of the glass label printing, the light passes through it, so it is very convenient to use it in backlit advertising and light boxes where the light is placed behind.

There is also a special type of glass label called letter sticker. In this type, the desired text or design is cut from the vinyl surface with the help of a plotter cutter, and after cutting, the other parts of the sticker remain on the surface. It is better not to use this type of sticker on colored surfaces, as it reduces the clarity of the image and the clarity of writing. For these surfaces, you can use gray back label printing.

All kinds of glass stickers

The transparent label sticker is available in the market in two types, matte and glossy. It is better to install a small sample of the clear adhesive back label before mass printing. Then print the rest if acceptable. In the modern art collection, glass labels are printed with the help of advanced machines, just like printing on a high-quality mesh. You can choose one of this type of printed label according to your usage.

Glass Label Printing Application

Adhesive glass vinyl is widely used in indoor and outdoor spaces. Among them, it can be used in all kinds of glass containers, bottles, transparent materials, etc. he is. Due to the transparent background of 3D poster printing, it is also possible to use it on ceramic and light-colored floors. The transparent label is also useful for displaying advertising banners. It is also used for outdoor printing and indoor printing for indoor and outdoor advertisements.

Among the other uses of this poster printing, we can refer to advertisements on cars, shop window decal printing, installation on the glass of shopping malls and offices, display of posters and billboards, even in the subway, on the wall and on the floor. Glass stickers are also used to decorate and beautify the interior and exterior spaces of homes and workplaces.

Why is printing on sticker glass boring?

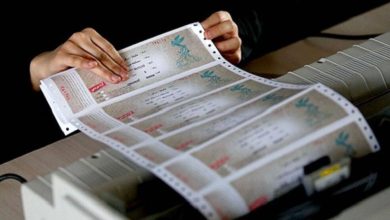

The printing of the glass decal may be a little faded and not have the effect you want. Therefore, if you plan to order a bulk glass label printing, be sure to see a sample of the printing before ordering in bulk. Clear labels are printed digitally and on a roll. You can request a sample. After sampling and testing the label printing and fixation on the desired material, proceed to printing a large number of glass labels.

How long does it take to print glass stickers?

Basically, anything kept in direct sunlight will have a shorter life compared to an indoor space. Adhesives that are installed outdoors and in direct light have a durability of up to 5 years. If you install this printed poster indoors and away from sunlight, it will have a lifespan of 15-20 years.

But the durability of the color of the ink, the printing machine and the printing are also effective. To increase color durability in glass label printing, lamination can be used. Especially if you have used an Ecosalont machine for printing, lamination of it increases the quality of work.

Laminating Poster Printing

Lamination is a covering over printed work that is stretched over after printing to prevent fading or the formation of streaks and scratches on the work. On the other hand, this makes the colors of the glass sticker more beautiful and more transparent. The thickness of the plate is very low (about 100 microns) and does not cause the label to thicken.

The difference between printing a glass label and a transparent label

Clear label printing is no different from glass label printing. Transparency is an English word meaning clear or colorless. Some people use clear stickers instead of glass stickers. Clear, transparent, clear, colorless and glass decal all have the same meaning.

What is the difference between glass label printing and glass label printing?

There is no difference between glass sticker and glass sticker, these kinds of stickers have adhesive and some call it glass sticker. All glass stickers are made of PVC. Modern Art Printing Kit prints logo on glass, glass label and prints on all PVC labels with excellent quality in the shortest time and free samples. It also has the ability to print glass labels with simultaneous cutting.

What is the price of a glass sticker?

The price of glass label printing depends on the type of paper, the printing machine, the quality of the printing ink, the color of the design, the number and dimensions of the prints. The glass posters in the Art Nouveau Collection are printed in the desired design and in the customer’s desired dimensions. The final cost of the printed product will be determined after determining the dimensions of the design, number of prints, device selection, and ink type.

Transparent label printing

Eco-solvent printing, solvent printing and UV printing are used to print glass labels. We explain the effectiveness of each of these elements below:

- Label printing with solvent printing machine has advantages such as long durability against sunlight and moisture. But the salon print quality is a bit low which is not suitable for indoor spaces and indoor advertising. Because solvent printing inks contain strong chemical compounds and are not compatible with the environment.

- It is very common to print labels with eco-salont printing machine. Because eco solvent inks are compatible with the environment and their printed designs can be used indoors. Ecosalont print quality is high and lasts longer.

- UV label printing is of high quality and long lasting, and it also has waterproof properties. But in terms of cost, it is more expensive than other types of label printing.

Arrangement of printing on glass vinyl

To print your design on a poster, you must send the design file you want in Tiff and PSD formats and in closed layers to the Art Novin group. Note that proper file quality will help increase the printing speed. Images must be in CMYK format with a resolution of at least 72 dpi. If there is a design problem, the problems will be investigated and resolved by art nouveau experts. After that, with your consent, the design is sent for printing.

The last word

This adhesive backing glass label printing allows you to attach your own text, design or logo to the product or to advertise to the desired level. This type of sticker is movable and can be moved easily after installation. An advantage of the glass decal is that it is transparent allowing you to see the color under the work when light passes through it. Art Noufen Printing Complex carries out the orders of printing posters of various types with excellent quality, the best materials and colors, and at reasonable prices for customers. For consultation, you can call the phone numbers listed on the website.

Tips for printing on glass

One way to beautify interior spaces is to use glass walls or tall windows. Especially if you want your lobby space or part of the house to be modern as well as bright. But if you want to choose luxurious wallpaper or curtains due to the simplicity of this type of material, then we have to tell you to back off! By printing on glass, you can get any kind of design you want on glass surfaces. Read this article to learn about the nuances of printing on glass.

How is glass printing done?

This type of printing, included in the bad felt printing category, is done using a device called bad felt. In glass printing, the used ink will be applied directly to the surface, and since the color fastness on the glass is very important, before printing begins, the surface of the glass is thoroughly cleaned. Then, according to your custom design, ink droplets are sprayed onto the surface and the drying process begins with UV light. This step, firstly, the ink does not move on the surface of the glass, and secondly, color stability is maintained during multi-layer printing.

The use of UV lamp for printing on glass increases the resistance of the ink in different weather conditions. If you like to use the printed glass in the open space and exposure to sunlight, this feature will make you feel comfortable. The cost of printing on glass is very reasonable regarding the quality and the output you get. This machine can give you the best quality digital printing with 1200dpi high resolution, which will be great if the original design is in high quality.

Types of printing on glass

This issue can be examined from several angles. It is one kind of printing machine used by the printing house. Depending on the capabilities of the device, it can be printed on transparencies, with local white, with backlight, resistant or anti-scratch coating. You can choose one of these depending on the design you want to print on the glass. On the other hand, the types of printing on glass can depend on the material of the glass, its dimensions, and its weight. For high-quality printing, tempered and raw glass are used. The suitable dimensions of the flat base machine are 2m by 3m max. The height of the device can also be changed up to 13 cm in thickness. Of course, you can also order smaller dimensions and thickness, such as 30 x 45 cm with a height of 8, according to the space you have.

What are the uses of printing on glass?

You can use this service to print your desired design on building windows, glass walls, cabinet dividers or shower enclosures. Although glass printing applications are not limited to the home and can be used for places such as stadiums, schools, hotels, tower lobbies, businesses and even exhibitions. Since you can print any color graphics on the glass, you can also use it as an advertising platform.

Also, in some cases, tempered glass is used as an automatic door or an elevator cabin. In short, wherever glass material can be used, you can count on design printing. Don’t worry about weather changes or constant sunlight. All products that reach your hands use UV technology, which creates high quality and durability of glass surfaces.

What features should the file we send for printing have?

If the area you want to print on is large, we suggest that you create the required graphic design with suitable dimensions. Image dimensions in graphic programs such as Photoshop and Illustrator, in addition to size, also have another criterion called resolution. Your submitted photo must be at least 100 pixels per inch. On the other hand, images above 200 PPI are not useful and the printable resolution cap is the same amount.

The next important issue is to discuss the colors you use in your design. If the work that you are going to send for printing is actually an image that you downloaded from the Internet or captured with a camera, you will need to go through the process of converting an RGB image to CMYK. But if you are going to create the required graphic file yourself, make sure the color mode of the file is set to CMYK and the color depth is set to 8 bits. Otherwise, you will experience color difference when printing.